In the fast-paced world of plastic manufacturing, thermoforming machines have become indispensable tools for creating a wide range of products. From everyday packaging to specialized industrial parts, these machines blend efficiency, flexibility, and cost-effectiveness—making them a top choice for businesses across sectors. To help you fully understand their value, we’ll break down what thermoforming machines are, how they work, and why they matter for modern production.

For a more dynamic understanding, a short video can showcase the thermoforming process in action—perfect for visual learners or teams training new operators:

A thermoforming machine is a manufacturing device designed to shape thermoplastic materials into specific forms. Unlike injection molding (which uses molten plastic injected into molds), thermoforming works by heating plastic sheets to a flexible state, then using pressure (vacuum or positive air) to press the softened plastic against a mold. Once cooled, the plastic retains the mold’s shape, and excess material is trimmed away to create the final product.

The primary goal of a thermoforming machine is to enable high-volume, cost-efficient production of plastic parts. Its strength lies in versatility: it can handle various thermoplastics (such as PET, PVC, and PP) and produce items of all sizes—from small medical components to large automotive panels. This adaptability makes it ideal for businesses balancing production speed, design flexibility, and budget.

A reliable thermoforming machine depends on several coordinated components, each playing a critical role in ensuring consistent, high-quality results. Here’s a breakdown of the most essential parts:

•Heating System: Equipped with infrared or convection heaters, this system warms the plastic sheet to its “forming temperature”—the sweet spot where the material is flexible but not melted. Precise temperature control is vital; too much heat damages the plastic, while too little prevents proper shaping.

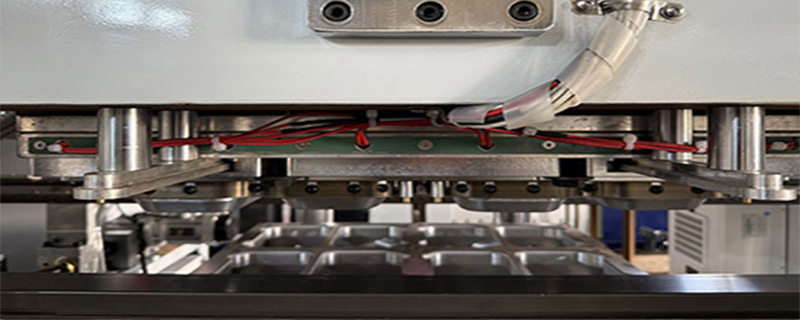

•Forming Station: The heart of the machine, this station holds the mold and applies pressure. Vacuum systems suck air from between the plastic and mold, pulling the material tight against the mold’s surface. For complex shapes, positive air pressure may push the plastic into the mold instead.

•Trimming Unit: After cooling, this component cuts away excess plastic to refine the product’s dimensions. Some machines integrate trimming into the main workflow, while others use separate units for intricate designs.

•Control Panel: A digital or manual interface that lets operators adjust settings like heating time, pressure levels, and cooling speed. Modern machines often include touchscreens for easier precision, reducing human error.

While thermoforming machines vary (from small manual models to large automated lines), their basic workflow follows a consistent pattern:

•Sheet Preparation: A roll or flat thermoplastic sheet is fed into the machine. Sheet thickness and material are chosen based on the product’s needs—thicker sheets for durability, thinner ones for lightweight items like packaging.

•Heating Phase: The sheet moves through the heating system, where it’s warmed evenly. This takes seconds to a minute, depending on the material and thickness.

•Forming Phase: The heated sheet is positioned over the mold. Vacuum or air pressure forces the plastic to conform to the mold’s shape, capturing every detail.

•Cooling Phase: The formed plastic is cooled (via fans or water-cooled molds) to harden and lock in the shape. Even cooling prevents warping, ensuring consistency.

•Trimming & Recycling: Excess plastic is trimmed off. Most trimmings are recycled back into production, making thermoforming a more sustainable option than other plastic manufacturing methods.

•Product Ejection: The finished product is removed from the machine, ready for inspection, packaging, or further assembly.

Thermoforming machines’ flexibility makes them vital across industries. Here are some of their most common uses:

•Packaging: The largest application—used for blister packs (pharmaceuticals/electronics), clamshells (toys/tools), and food trays (meats, ready meals). It creates lightweight, protective packaging that showcases products.

•Healthcare: Produces sterile parts like medical device housings, diagnostic kit components, and surgical trays. It works with medical-grade plastics (non-toxic, sterilization-resistant) to meet safety standards.

•Automotive: Makes interior parts such as door panels, dashboard components, and seat covers. It’s cost-effective for low-to-medium volume production and allows for custom textures.

•Consumer Goods: Creates household items (storage containers, appliance parts), toys, and sports equipment housings—balancing functionality and design.

If you’re considering a thermoforming machine for your production line, keep these factors in mind:

•Material Compatibility: Ensure the machine works with your chosen thermoplastics (e.g., PET for food packaging, PVC for medical parts).

•Production Volume: Manual/semi-automated machines suit small batches; fully automated models handle high-volume needs. Check cycle time (time per unit) to match your goals.

•Mold Flexibility: Opt for machines with quick-change mold systems if you plan to produce multiple designs—this cuts downtime between runs.

•Automation Level: Fully automated machines reduce labor but cost more; semi-automated options are budget-friendly but need more operator input.

•After-Sales Support: Choose a supplier that offers maintenance, parts, and technical support—downtime can hurt productivity, so reliable support is key.

Thermoforming machines aren’t just tools—they’re drivers of innovation, helping businesses create products that meet consumer demands while staying efficient. Whether you’re new to thermoforming or upgrading equipment, understanding these basics is the first step to unlocking their potential.

If you’re ready to optimize your production with a thermoforming machine, our team of experts can help. We’ll guide you through material selection, machine specs, and workflow integration to find the right fit for your business. Reach out Sinoplast today for a free consultation—let’s turn your production goals into reality.

AI Contribution: Less than 30% (This content was written primarily by human industry experts, with minimal AI help for structure fine-tuning. All explanations, workflows, and tips reflect hands-on manufacturing knowledge to ensure authenticity and practicality.)

We are a professional plastic machinery provider in China.