Thermoforming continues to revolutionize plastic manufacturing, offering unmatched versatility across industries such as food packaging, medical supplies, automotive components, and consumer goods. With its ability to produce high-quality, lightweight, and cost-effective products, thermoforming is increasingly favored by businesses seeking scalability, material efficiency, and rapid production cycles.

1. Food Packaging – Thermoformed PET, PP, and PS containers, including clamshells, meal boxes, and cup lids, ensure hygiene, durability, and compliance with food safety standards.

2. Sustainable Packaging Solutions – With growing environmental regulations, thermoforming supports recycled-content packaging, such as rPET trays, meeting circular economy demands.

3. Medical & Pharmaceutical – Blister packs, surgical trays, and sterile packaging benefit from thermoforming’s precision and material adaptability.

4. Industrial & Automotive – Custom protective packaging, interior trim components, and disposable industrial trays leverage thermoforming’s strength and design flexibility.

Governments worldwide are implementing policies to promote sustainable packaging, creating new opportunities for thermoformed products. For example:

Spain’s 2024 Packaging Cost Adjustments:

Hot-formed PET packaging may enjoy discounts, incentivizing eco-friendly production.

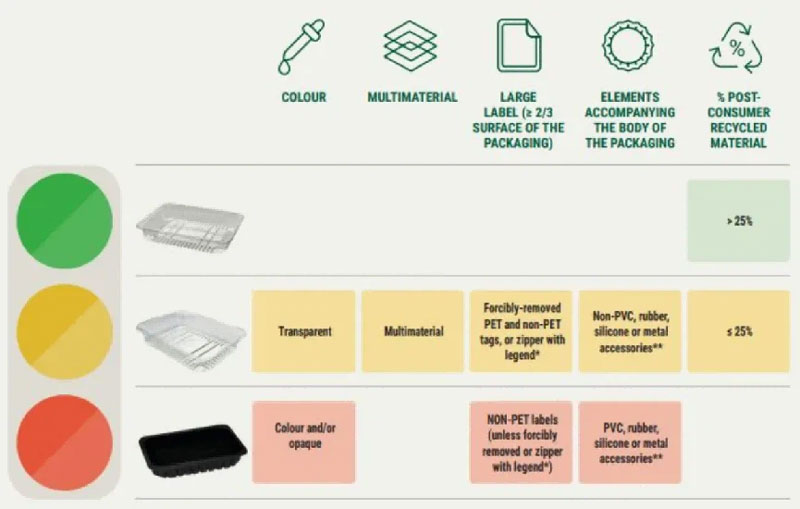

Packaging with >25% post-consumer recycled (PCR) materials qualifies for a 5.5% cost subsidy, while colored/opaque packaging faces a 10% surcharge.

Companies can obtain RETRAY certification (EN 15343) under ISO/IEC 17065 to validate recycled content, ensuring compliance and market competitiveness.

This policy encourages upstream-downstream collaboration, pushing manufacturers to adopt high-efficiency thermoforming solutions that align with sustainability goals.

To meet rising demand for high-speed, low-waste production, innovative machinery like the Sinoplast Plastic Cup Thermoforming Machine (multi-station design) delivers:

Unmatched Speed: Up to 40 cycles/min (PET) and 30 cycles/min (PP), ideal for disposable food packaging, egg trays, and fruit containers.

Large-Format Production: Forming plates (780x540mm / 780x650mm) enable multi-cavity molds, boosting output.

Smart Automation: Preset mold parameters reduce setup time, while energy-efficient operation cuts costs.

Material Versatility: Processes PP, PET, PS, and recycled-content sheets, supporting sustainable manufacturing.

As global markets shift toward eco-friendly packaging, thermoforming stands out as a cost-effective, high-speed, and adaptable solution. With regulatory incentives (like Spain’s PCR subsidies) and advanced machinery (such as Sinoplast’s thermoforming systems), businesses can reduce costs, enhance sustainability, and stay ahead of industry trends.

Upgrade your production with Sinoplast’s cutting-edge thermoforming technology—where efficiency meets environmental responsibility!

References:

Spain’s 2024 packaging cost adjustments (industry reports).

RETRAY certification & EN 15343 standards for recycled materials.

Would you like further customization for a specific market or product focus?

We are a professional plastic machinery provider in China.