A plastic cup-making machine is specialized equipment for producing disposable plastic products such as cups, bowls, and plates. Its working principle is to use a servo feeding system to transport PP/PET sheets to a heating box for heating and softening. The softened sheets are then transported to the forming station for molding using molds, and finally stacked by a belt-type automatic cup stacking machine or robotic arm.

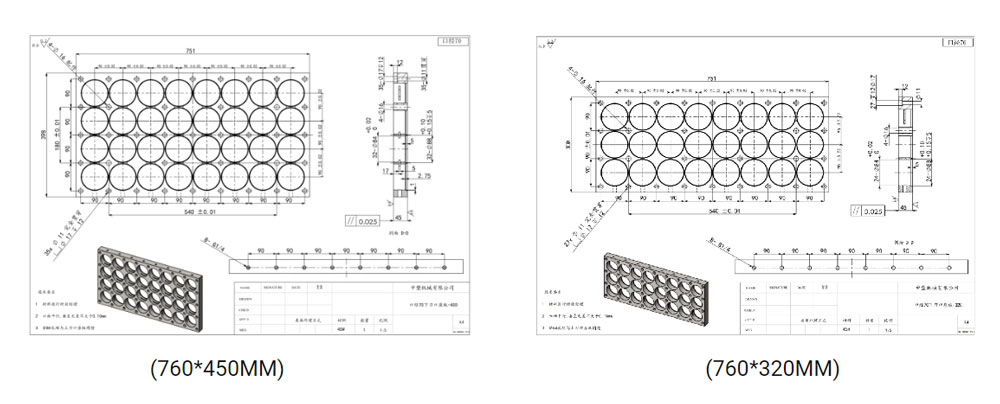

1. Molding layout of equipment: The larger the molding layout of the equipment, the more cavities the mold can accommodate. For example, when producing a cup with a diameter of 70 MM, a layout of 760 x 320 MM can produce 24 chambers, while a layout of 760 x 450 MM can produce 32 chambers. Therefore, after each molding, the layout of 760 x 450MM will produce 8 more cups than the layout of 760 x 320MM

2. Material of cups: When using a plastic cup machine to produce PP material cups, the operating speed is generally slower than that of PET material cups, because PP sheets require higher temperatures to soften and also need some time to cool after the mold is formed. If the running speed is too fast, it may cause problems such as whitening of the bottom of the PP cup or improper molding

3. Stacking method: The Sinoplast cup thermoforming machine offers two stacking methods: one uses a robotic arm for stacking, and the other uses a belt-type automatic cup stacking machine for stacking. If customers can choose a belt-type automatic cup stacking machine for cup production, because, after forming, the cups will be demolded and blown out by air, and then stacked by the belt-type automatic stacking machine. If using a robotic arm for stacking, it takes some time for the robotic arm to grasp after forming

4. Equipment structure: The driving structure of plastic cup-making machines is often an important factor affecting their operating speed. Now our equipment adopts the eccentric wheel drive method, which can ensure the stability of the machine under long-term high-speed operation. Meanwhile, the eccentric wheel has high durability.

In summary, the production speed of plastic cup-making machines is comprehensively affected by multiple factors. The core Key Technical Points are as follows:

Equipment molding layout: It determines the number of cavities the mold can accommodate, thereby affecting the number of products per molding cycle, which is a fundamental factor for output efficiency.

Cup material properties: Different materials (PP/PET) have different heating and cooling requirements. PP material requires a higher softening temperature and longer cooling time, which restricts the machine's operating speed to avoid product defects.

Stacking method: The belt-type automatic stacking mode is more efficient than robotic arm stacking, as it reduces post-forming waiting time by air demolding and immediate stacking.

Equipment driving structure: The eccentric wheel drive method ensures the machine's stability and durability under long-term high-speed operation, laying a reliable foundation for high-speed production.

Optimizing these TKD reasonably can effectively improve production speed while ensuring product quality and equipment stability.

Prev:

null

We are a professional plastic machinery provider in China.