The Thermoforming Machine by Sinoplast is specifically designed for plastic food packaging solutions,The whole machine adopts the latest exterior design, which integrates Sinoplast’s signature branding elements.

The new generation of thermoforming machines combines the high-end configurations with more practical functions, making it the preferred choice for plastic packaging manufacturers who pursue efficiency and speed.

Maximum Forming Layout:780*650MM, provides more cavities for thermoforming molds.

Cycle Speed:45molds/min,Ensures product quality under high-speed and stable production conditions

Maximum Forming Depth: 140MM,Capable of handling thermoformed products of various types and depths

This thermoforming machine supports a variety of materials, including PP, PET, PS, and PLA. The maximum sheet thickness can reach up to 2.5MM, making it an ideal choice for producing disposable plastic products such as fruit boxes, lunch boxes, and plates.

Operating Power: 50-60KW ,Provides more energy-efficient solutions for long-term operation

Kinetic Energy Recovery:During the operation, unused electricity is collected and recycled for reuse

Sinoplast’s thermoforming machine can ensure energy efficiency and provide users with more reliable production needs even in high-yield production situations

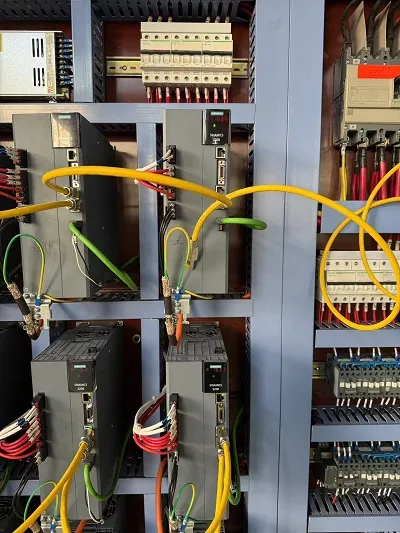

Control System: Equipped with servo motors and PLC control to achieve precise control and automation

Memory Function:Users can store the operating parameters of each set of molds to avoid resetting them due to mold replacement

SINOPLAST was founded in 2013 and is a globally recognized supplier of thermoforming machines, dedicated to providing sustainable and recyclable plastic packaging solutions.

The company's services include mold design, manufacturing, installation, and commissioning. SINOPLAST is a trusted partner for thermoformed packaging manufacturers, with over a decade of experience representing innovative technology, first-class quality, and excellent service

|

Model |

SPM-780E |

SPM-780D |

SPB-780E |

SPB-780D |

|

Station Number |

3 |

4 |

3 |

4 |

|

Max.Forming Area |

780*540MM |

780*650MM |

||

|

Max.Forming Depth |

140MM |

|||

|

Suitable Material |

PP/PS/PET |

|||

|

Sheet Width |

550-820MM |

|||

|

Material Thickness Range |

0.15-2.5MM |

|||

|

Max. Sheet Roll Dia. |

1200MM |

|||

|

Running Speed |

35-40Cycles/min |

|||

|

Forming Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Forming station stretching |

Servo Motor 7 KW |

|||

|

Hole Punching Station Power |

NONE |

Servo Motor 14 KW |

NONE |

Servo Motor 14 KW |

|

Cutting Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Stacking Station Power |

Servo Motor 3.5 KW |

|||

|

Sheet Feeding Method |

Servo Motor 5 KW |

|||

|

Air Consumption/Air Pressure |

3m3/min,0.6-0.8Mpa

|

|||

|

Power Voltage |

380V,50Hz 3P |

|||

|

Approx. Machine Weight |

17T |

21T |

17.5T |

21.5T |

Cylinder lifting system

Automatic sheet feeding

Able to work with double roll

Max.roll diameter:1200MM

Servo motor control

Aluminum alloy strip cooling

Automatic lubrication of the chain(PLC control)

Can stretch the sheet material

Oven size: Up and down 13 * 10 MM

Equipped with anti sheet falling sensor

Adopting German Elstein ceramic heater

Maximum forming depth:140 MM

4 pillar supports

Maximum Forming Layout:780*650 MM

Max. stroke:160 MM

Cylinder lock mold

Adopting a vacuum suction structure, each air tube is independently connected to the gas source to ensure that one product is not sucked in and affects other products.

High quality electronic components ( SIEMENS, OMRON, SEW, SCHNEIDER )

High power cabinet air conditioner

Canada

Peru

Ecuador

Guyana

Ghana

Saudi Arabia

Egypt

Kenya

Dubai

Sri Lanka

Vietnam

Iraq

Bangladesh

India

Jordan

Nigeria

Pakistan

We are a professional plastic machinery provider in China.