The SPB-780D thermoforming machine is high-performance and efficient equipment designed specifically for the large-scale production of disposable plastic products. It is also the largest molding layout equipment launched by Sinoplast to date, with a molding layout of 780 x 650mm, making it an ideal choice for producing disposable plastic items such as egg boxes, sauce cups, and trays.

The machine adopts a new design concept and a future oriented control system. For example, in order to enable customers to monitor the real-time electricity consumption and output of machines more intuitively during the production process, we have added a power calculation function in the program. Customers can input the electricity price per kilowatt in their country, and the thermoforming machine will automatically calculate real-time electricity consumption to ensure the efficiency and stability of the entire production process.

The Sinoplast thermoforming machine uses a built-in eccentric wheel drive structure. The Sinoplast thermoforming machine uses a built-in eccentric wheel drive structure. When using PP sheets, its maximum operating speed can reach 30 molds per minute, while PET sheets allow for speeds of up to 40 molds per minute. The thickness of the sheet and the depth of the product are also key factors in determining the machine's operating speed, as deeper products require longer molding times.We recommend setting the operating speed to 20–30 molds per minute for optimal production performance and quality.

When purchasing our plastic thermoforming machine, you don't have to worry about installation issues. After the machine arrives at the customer's factory, we will send an engineer to the customer's factory for installation and debugging. Our engineers will also save the operating parameters of each set of molds in the equipment program. If the customer changes the mold for production, there is no need to re debug. Just install the mold on the mold table and start production according to the initially saved operating parameters.

|

Model |

SPM-780E |

SPM-780D |

SPB-780E |

SPB-780D |

|

Station Number |

3 |

4 |

3 |

4 |

|

Max.Forming Area |

780*540MM |

780*650MM |

||

|

Max.Forming Depth |

140MM |

|||

|

Suitable Material |

PP/PS/PET |

|||

|

Sheet Width |

550-820MM |

|||

|

Material Thickness Range |

0.15-2.5MM |

|||

|

Max. Sheet Roll Dia. |

1200MM |

|||

|

Running Speed |

35-40Cycles/min |

|||

|

Forming Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Forming station stretching |

Servo Motor 7 KW |

|||

|

Hole Punching Station Power |

NONE |

Servo Motor 14 KW |

NONE |

Servo Motor 14 KW |

|

Cutting Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Stacking Station Power |

Servo Motor 3.5 KW |

|||

|

Sheet Feeding Method |

Servo Motor 5 KW |

|||

|

Air Consumption/Air Pressure |

3m3/min,0.6-0.8Mpa

|

|||

|

Power Voltage |

380V,50Hz 3P |

|||

|

Approx. Machine Weight |

17T |

21T |

17.5T |

21.5T |

Cylinder lifting system

Automatic sheet feeding

Able to work with double roll

Max.roll diameter:1200MM

Servo motor control

Aluminum alloy strip cooling

Automatic lubrication of the chain(PLC control)

Can stretch the sheet material

Oven size: Up and down 13 * 10 MM

Equipped with anti sheet falling sensor

Adopting German Elstein ceramic heater

Maximum forming depth:140 MM

4 pillar supports

Maximum Forming Layout:780*650 MM

Max. stroke:160 MM

Cylinder lock mold

Adopting a vacuum suction structure, each air tube is independently connected to the gas source to ensure that one product is not sucked in and affects other products.

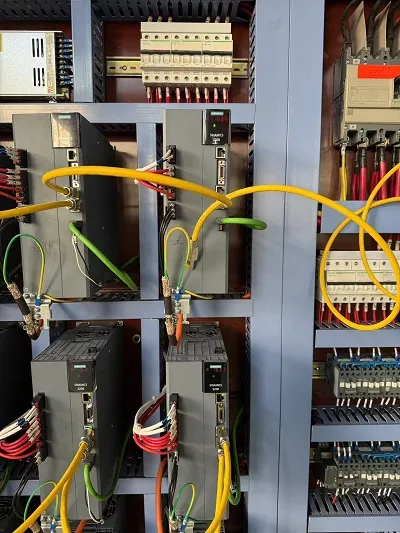

High quality electronic components ( SIEMENS, OMRON, SEW, SCHNEIDER )

High power cabinet air conditioner

Canada

Peru

Ecuador

Guyana

Ghana

Saudi Arabia

Egypt

Kenya

Dubai

Sri Lanka

Vietnam

Iraq

Bangladesh

India

Jordan

Nigeria

Pakistan

We are a professional plastic machinery provider in China.