A disposable plastic food container machine works by heating plastic sheets until they soften, then shaping them into specific products using molds. Widely used in the plastic packaging industry, this versatile machine allows manufacturers to produce a variety of products simply by changing molds. For larger items like cake boxes and lunch boxes, a machine with a bigger molding area is essential, as it accommodates more cavities per mold, increasing efficiency. This model features a maximum molding area of 780 × 650 mm and a maximum forming depth of 105 mm, making it ideal for producing larger, deeper items.

The SP-780 plastic tray making machine features four workstations: molding, cutting, punching, and stacking. This configuration is essential for producing certain items, such as fruit packaging boxes, cup lids, and other plastic products. Each workstation operates with two servo motors, ensuring high precision and efficiency.

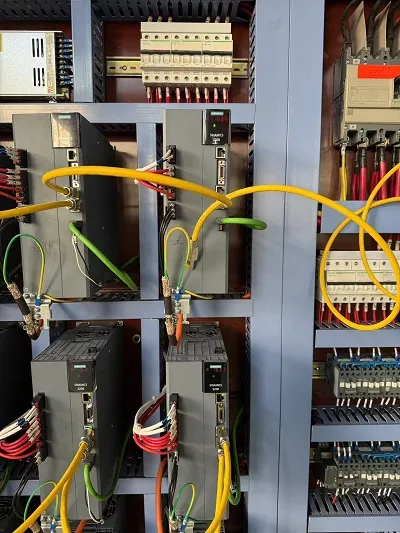

When customers purchase our equipment, we provide various configuration options to suit their needs, including choices for heating elements. They can select heating elements from the renowned German brand ELSTEIN or a trusted Chinese brand. Our standard equipment comes equipped with Siemens servo motor drives and Siemens electronic components from Germany. If customers have specific brand preferences, we can customize the equipment accordingly.

As awareness of environmental protection grows and the demand for high-quality plastic products increases, plastic thermoforming machines have become essential in the industry.

|

Model |

SPM-780E |

SPM-780D |

SPB-780E |

SPB-780D |

|

Station Number |

3 |

4 |

3 |

4 |

|

Max.Forming Area |

780*540MM |

780*650MM |

||

|

Max.Forming Depth |

140MM |

|||

|

Suitable Material |

PP/PS/PET |

|||

|

Sheet Width |

550-820MM |

|||

|

Material Thickness Range |

0.15-2.5MM |

|||

|

Max. Sheet Roll Dia. |

1200MM |

|||

|

Running Speed |

35-40Cycles/min |

|||

|

Forming Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Forming station stretching |

Servo Motor 7 KW |

|||

|

Hole Punching Station Power |

NONE |

Servo Motor 14 KW |

NONE |

Servo Motor 14 KW |

|

Cutting Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Stacking Station Power |

Servo Motor 3.5 KW |

|||

|

Sheet Feeding Method |

Servo Motor 5 KW |

|||

|

Air Consumption/Air Pressure |

3m3/min,0.6-0.8Mpa

|

|||

|

Power Voltage |

380V,50Hz 3P |

|||

|

Approx. Machine Weight |

17T |

21T |

17.5T |

21.5T |

Cylinder lifting system

Automatic sheet feeding

Able to work with double roll

Max.roll diameter:1200MM

Servo motor control

Aluminum alloy strip cooling

Automatic lubrication of the chain(PLC control)

Can stretch the sheet material

Oven size: Up and down 13 * 10 MM

Equipped with anti sheet falling sensor

Adopting German Elstein ceramic heater

Maximum forming depth:140 MM

4 pillar supports

Maximum Forming Layout:780*650 MM

Max. stroke:160 MM

Cylinder lock mold

Adopting a vacuum suction structure, each air tube is independently connected to the gas source to ensure that one product is not sucked in and affects other products.

High quality electronic components ( SIEMENS, OMRON, SEW, SCHNEIDER )

High power cabinet air conditioner

Canada

Peru

Ecuador

Guyana

Ghana

Saudi Arabia

Egypt

Kenya

Dubai

Sri Lanka

Vietnam

Iraq

Bangladesh

India

Jordan

Nigeria

Pakistan

We are a professional plastic machinery provider in China.