The SPM-780E thermoforming machine, also known as a three station thermoforming machine, has a forming area of 780 x 540 MM and is an ideal choice for customers who pursue high output. The larger the molding area, the more mold cavities there are, thereby increasing production. For example, when producing products of the same size, a 780 x 540mm layout can accommodate 20 cavities, while a 680 x 450mm layout typically can only accommodate 10 cavities. This means that the 780 x 540mm machine can produce an additional 10 products after each molding, significantly increasing production output.

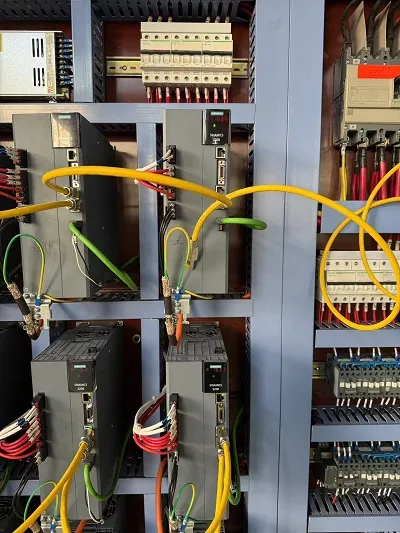

The whole plastic lunch box making machine is equipped with a total of 6 servo motors, one located for feeding and one for stacking. Two for molding and two for cutting. Servo motor drive has high-precision positioning capability, which can meet the high-precision application requirements. At the same time, servo motor drive has a large overload capacity, which can withstand large loads in a short period of time without damage, thereby improving the quality of the machine.

The Sinoplast Thermoforming Machine is designed for three-phase 380V/50HZ power supply. Due to variations in voltage across different countries, we can customize according to customer requirements.

|

Model |

SPM-780E |

SPM-780D |

SPB-780E |

SPB-780D |

|

Station Number |

3 |

4 |

3 |

4 |

|

Max.Forming Area |

780*540MM |

780*650MM |

||

|

Max.Forming Depth |

140MM |

|||

|

Suitable Material |

PP/PS/PET |

|||

|

Sheet Width |

550-820MM |

|||

|

Material Thickness Range |

0.15-2.5MM |

|||

|

Max. Sheet Roll Dia. |

1200MM |

|||

|

Running Speed |

35-40Cycles/min |

|||

|

Forming Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Forming station stretching |

Servo Motor 7 KW |

|||

|

Hole Punching Station Power |

NONE |

Servo Motor 14 KW |

NONE |

Servo Motor 14 KW |

|

Cutting Station Power |

Servo Motor 7 KW*2 pcs |

|||

|

Stacking Station Power |

Servo Motor 3.5 KW |

|||

|

Sheet Feeding Method |

Servo Motor 5 KW |

|||

|

Air Consumption/Air Pressure |

3m3/min,0.6-0.8Mpa

|

|||

|

Power Voltage |

380V,50Hz 3P |

|||

|

Approx. Machine Weight |

17T |

21T |

17.5T |

21.5T |

Cylinder lifting system

Automatic sheet feeding

Able to work with double roll

Max.roll diameter:1200MM

Servo motor control

Aluminum alloy strip cooling

Automatic lubrication of the chain(PLC control)

Can stretch the sheet material

Oven size: Up and down 13 * 10 MM

Equipped with anti sheet falling sensor

Adopting German Elstein ceramic heater

Maximum forming depth:140 MM

4 pillar supports

Maximum Forming Layout:780*650 MM

Max. stroke:160 MM

Cylinder lock mold

Adopting a vacuum suction structure, each air tube is independently connected to the gas source to ensure that one product is not sucked in and affects other products.

High quality electronic components ( SIEMENS, OMRON, SEW, SCHNEIDER )

High power cabinet air conditioner

Canada

Peru

Ecuador

Guyana

Ghana

Saudi Arabia

Egypt

Kenya

Dubai

Sri Lanka

Vietnam

Iraq

Bangladesh

India

Jordan

Nigeria

Pakistan

We are a professional plastic machinery provider in China.